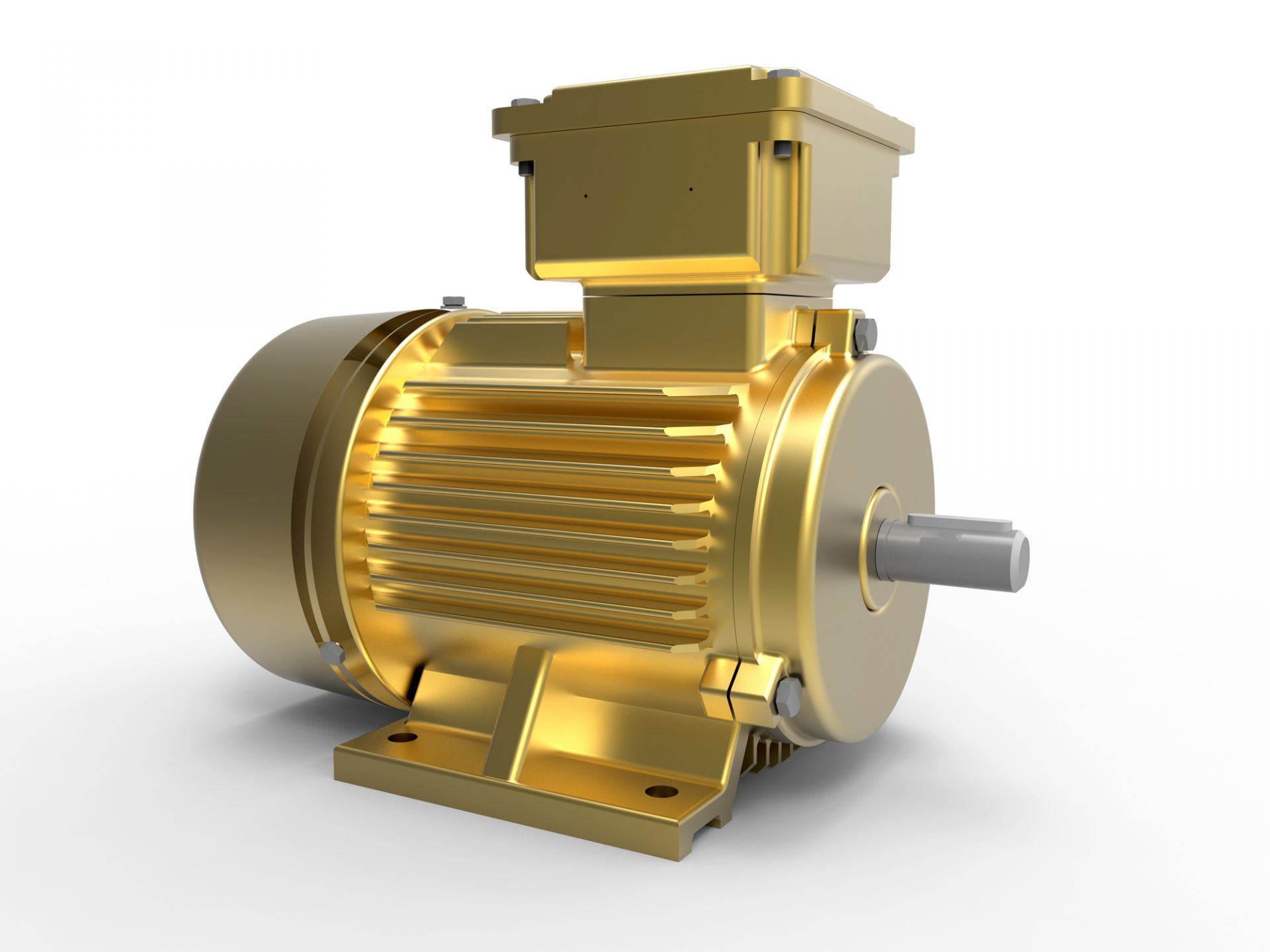

The price of an electric motor depends on many factors. Raw materials that make up a motor are essentially copper, aluminum, cast iron and steel, which also includes electrical sheet. Labor and energy costs are incurred in the country of manufacture, and transportation to Central Europe is usually by sea or rail. The various costs are incurred in different currencies, so exchange rates are also relevant for the final price.

Raw materials market remains turbulent

Prices for industrial metals, measured in dollars per ton, are now below their peaks in spring 2022, but compared to 2020, the price is still very high. In U.S. currency, copper is about 20% more expensive, aluminum about 40%. For us in Europe, prices have risen more, but the euro has lost more than 15% of its purchasing power against the dollar over the same period.

The price of electric sheet metal is unpredictable. They are stamped from steel, which must meet certain electrical properties. Higher efficiency of the motor needs higher quality of steel, therefore there is no price for it on the stock exchange. There is only a price for pig iron, but it says nothing about steel. If production stops in steel mills, pig iron becomes cheaper and steel more expensive. There are repeated production stoppages in steel mills, especially in the important production countries of Ukraine and China. For example, on Aug. 17, 2022, the Shanghai Metals Market platform reported the closure of nearly 20 steel mills in western China because energy is being rationed.

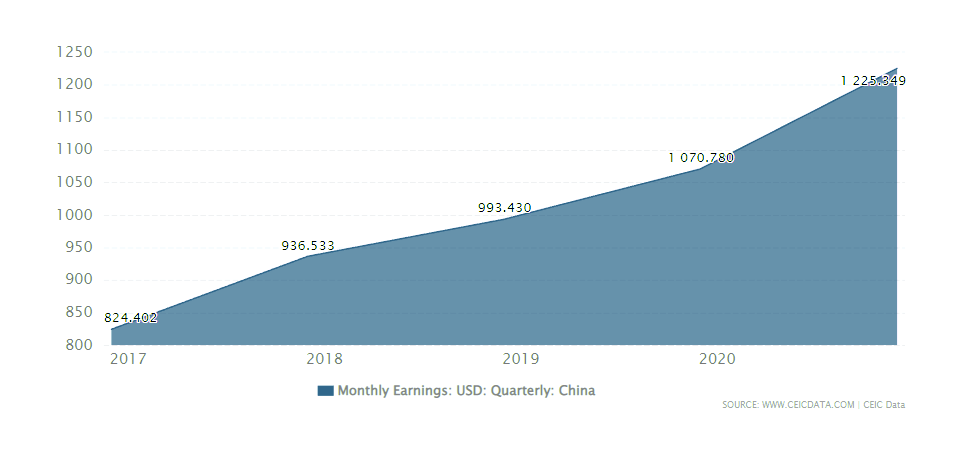

Labor and energy costs are gaining importance

Labor costs are a factor that could often be ignored in the past. Workers have earned more each year, but productivity has also increased, for example, through automation. But pandemic-related work stoppages, skills shortages and rising housing costs now exist around the world. Labor costs have risen particularly sharply in China and the Czech Republic; MOLL-MOTOR sources many engines from both countries.

Energy costs also used to receive little attention. Now they are rising many times over and manufacturers are charging us energy surcharges for orders that have already been confirmed. Unfortunately, we had to accept corresponding changes in the general terms and conditions, so these subsequent price increases are legally covered. In contrast, MOLL-MOTOR has decided to do without such passages in the GTC. We want to keep this basic decision as long as we can still cope with the price risk. Because our priority is reliable business relations with our customers. Sticking to confirmed prices is an important building block for this.

Chaos in the ports

Energy costs are one of the reasons why transport costs have remained at an extremely high level for months. In two years, the price to ship a 20-foot container from China to Hamburg has more than quintupled. In addition, supply chains are completely out of rhythm, with disruptions spreading across the globe and reinforcing each other. Weeks after port closures in China, many ships arrive in the North Sea at the same time. Ports try to work through the congestion quickly, but after several instances, overworked port staff go on strike and new congestion ensues. Currently, the average ship waiting time in Hamburg is 10-20 days, in extreme cases up to 34 days. Therefore, ships unload the goods in other ports where onward transportation is not ensured. Demurrage and transshipment costs have to be paid and freight forwarders unanimously refuse to assume this cost risk. Since all additional costs are passed on 100% to the customer, the true freight price is not known until the goods have arrived.

Maximum reliability at MOLL-MOTOR

In this difficult environment, we strive daily to offer our customers delivery reliability and price stability. Special thanks are due to our logistics staff for their commitment, with which they have already saved many situations. Fortunately, our contacts at customers, freight forwarders and suppliers also usually understand our situation. Strengthened by this stable network, we reliably supply the economy with electric motors, drive and automation technology even in times of crisis.