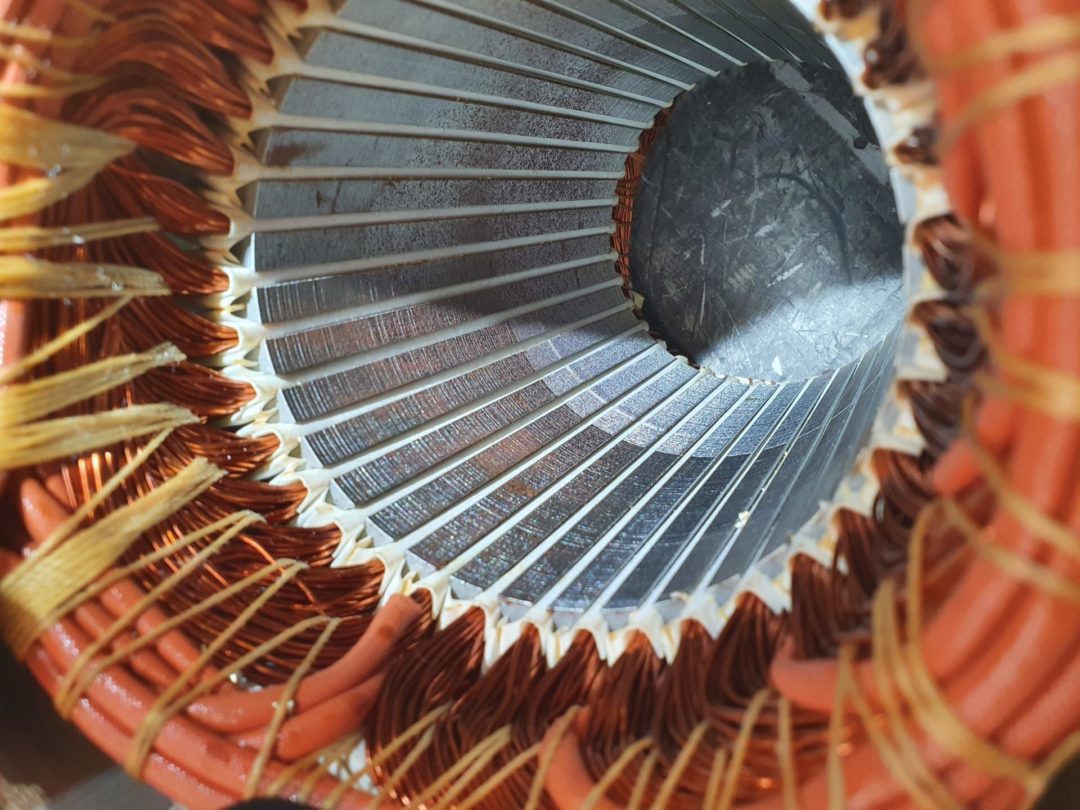

We still repair and trade in electric motors today. In order to meet the requirements of drive technology and thus customer needs, we can make numerous modifications to motors.

- For example, if we do not have a motor in stock in the required mounting form (IM B3, IM B5, IM B14, IM B35, IM B34), we can modify the motor using our flange end shields and/or feet. For installation position IM V1, angular contact ball bearings are recommended; this modification is also possible with us. Another option is current-insulated bearings for frequency converter operation or bearings for increased radial load.

- Depending on the place of use, conversion to a tropicalized version for ambient temperatures from -20°C to -40°C or adaptation of the protection class (IP56/IP65/IP66), i.e. protection against dust and splash water, is recommended.

- Brake kits offer us great flexibility in our product range. Standard motors can be converted to brake motors with them. The rapid availability of brake motors in various sizes and pole numbers is greatly appreciated by many of our customers.

- In our in-house paint shop, motors are repainted according to customer requirements. In addition to our standard grey color, motors are therefore available in all colors. Epoxy paintwork is also possible.

- Assembly with other drive technology components, such as a gearbox, is also carried out in-house. Gearboxes from the Italian manufacturer Bonfiglioli can be built from stock in our workshop. We manufacture planetary gearboxes (300 series), bevel gearboxes (A series), helical gearboxes (C, S series) and parallel shaft gearboxes (F series) in various sizes, versions, installation positions and ratios.

- The following options and modifications are also available on request for three-phase squirrel cage motors of Y3PE, Y2PE and Y2SEA series:

Installation of motor protection PTC thermistor (if not standard), PTO – temperature monitor for switch-off (Clixon/NC or NO contact), PT100 resistance thermometer, winding insulation class “H”, change of terminal box position, rain canopy, return stop, condensation drain hole, metal fan blade, extended warranty, preparation for rotary encoder, pot motor

Drive solution according to customer requirements

In many cases, not only a suitable motor is required, but a drive solution that is perfectly tailored to the requirements and wishes of our customers. Therefore, we combine motors, gearboxes, couplings and frequency inverters and select the best combination of different manufacturers in terms of technology and the dimensions of the respective products. We plan and manufacture control cabinets for complex control systems, both in individual production and in series production. For example, one of our designed control cabinets controls a vacuum packaging system for a large company in Upper Austria.

Warehousing

Our many years of experience and flexibility in designing the right drive are rounded off by our high stock availability. Over 70,000 motors, gearboxes, frequency inverters and output elements are available at our site in Stockerau. In this way drives with standard outputs can be provided quickly.

Contact or visit us, we will be happy to advise you on the right choice of drive. MOLL-MOTOR, your partner for drive technology.