Repairable drum motors have decisive advantages

| 1 | Bolted end covers: In contrast to glued variants, bolted end covers allow easy access to the inside of the motor. This makes maintenance and repair work much easier and reduces downtime. |

| 2 | Robust end covers: Damage caused by external influences is minimized if the end covers are made of cast iron and not aluminium. |

| 3 | Robust gear parts: Gear parts made of high-alloy, pressure-hardened steel offer greater strength and durability. |

| 4 | Ground gearbox parts: Many manufacturers rely on milled parts. Gears with ground and planed tooth flanks, on the other hand, offer longer service life and oil durability as well as lower noise levels. |

| 5 | Larger bearings: The dimensions of ball and needle bearings have a major influence on the rotational speed of the rolling elements and therefore on wear. Larger bearing dimensions promise a longer service life. |

| 6 | Rapid availability of spare parts: Spare parts for high-quality drum motors are generally available worldwide within 24 to 48 hours, which enables rapid repairs. |

MOLL-MOTOR offers repair and replacement

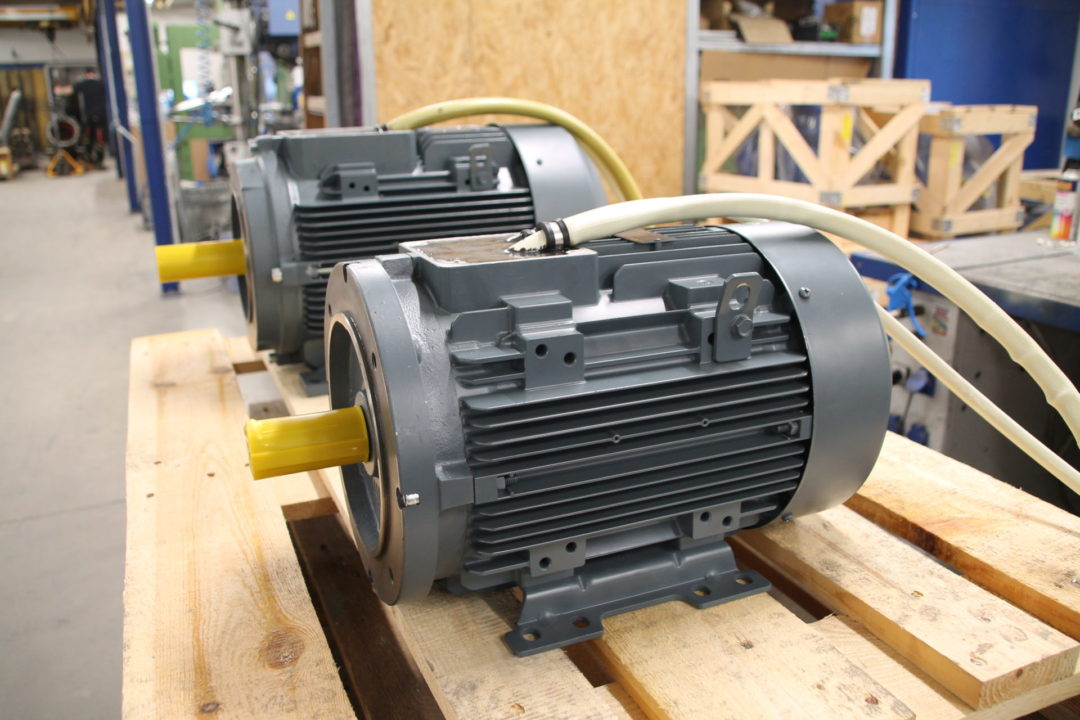

The use of repairable drum motors with bolted end covers and robust materials offers long-term advantages in terms of ease of maintenance, reliability and operational safety. Particularly in critical applications where downtime can cause considerable costs, investing in high-quality, repairable drum motors is an economically sensible decision.

With MOLL-MOTOR you have all the options: Identical replacements, upgrade to identical attachable repairable premium drum motor, as well as quick repair if the model allows it. OEMs can also purchase large quantities of drum motors from MOLL-MOTOR. Thanks to our large portfolio, we can find the right product for both price-sensitive and quality-oriented machine manufacturers.

For further information or individual advice, please do not hesitate to contact us.