Vacuum packaging is a quick and practical way to preserve and store food. The technology is so popular that even private individuals can buy small vacuum packaging machines for the home from electronics retailers. However, in large cheese-making or butchery operations, it is inefficient to run a separate machine at each packing station. To save energy and costs, therefore, more and more large-scale operations are using centralized systems that always ensure the right vacuum so that packaging can be done quickly and efficiently.

Efficiency through central control

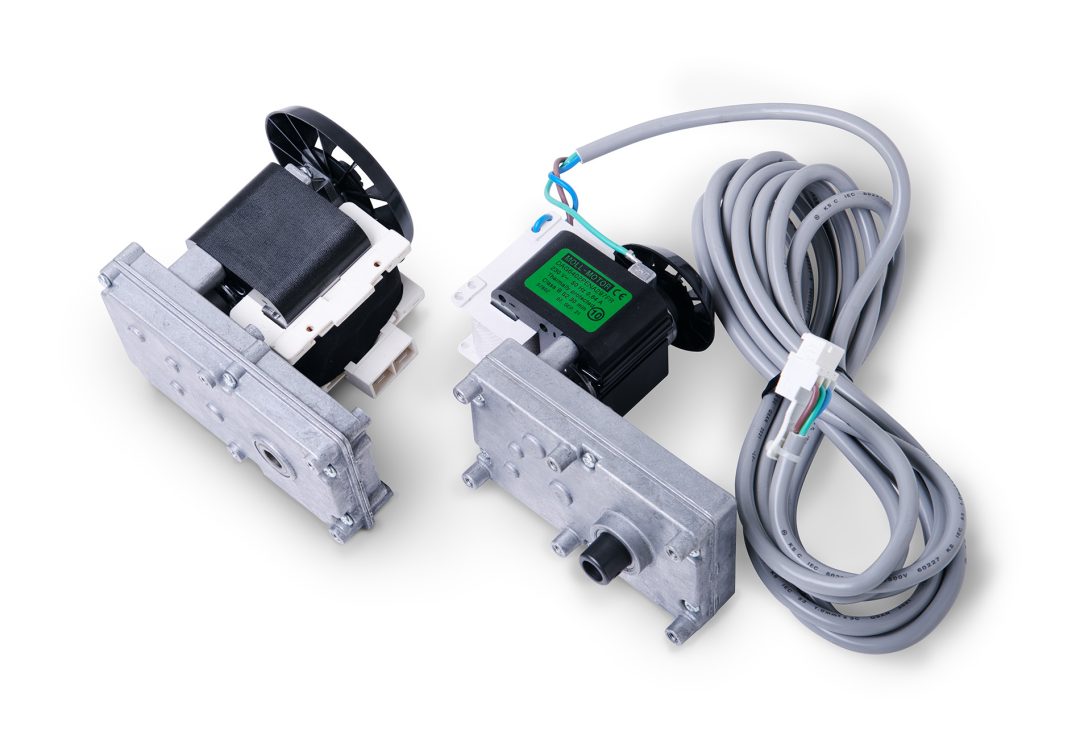

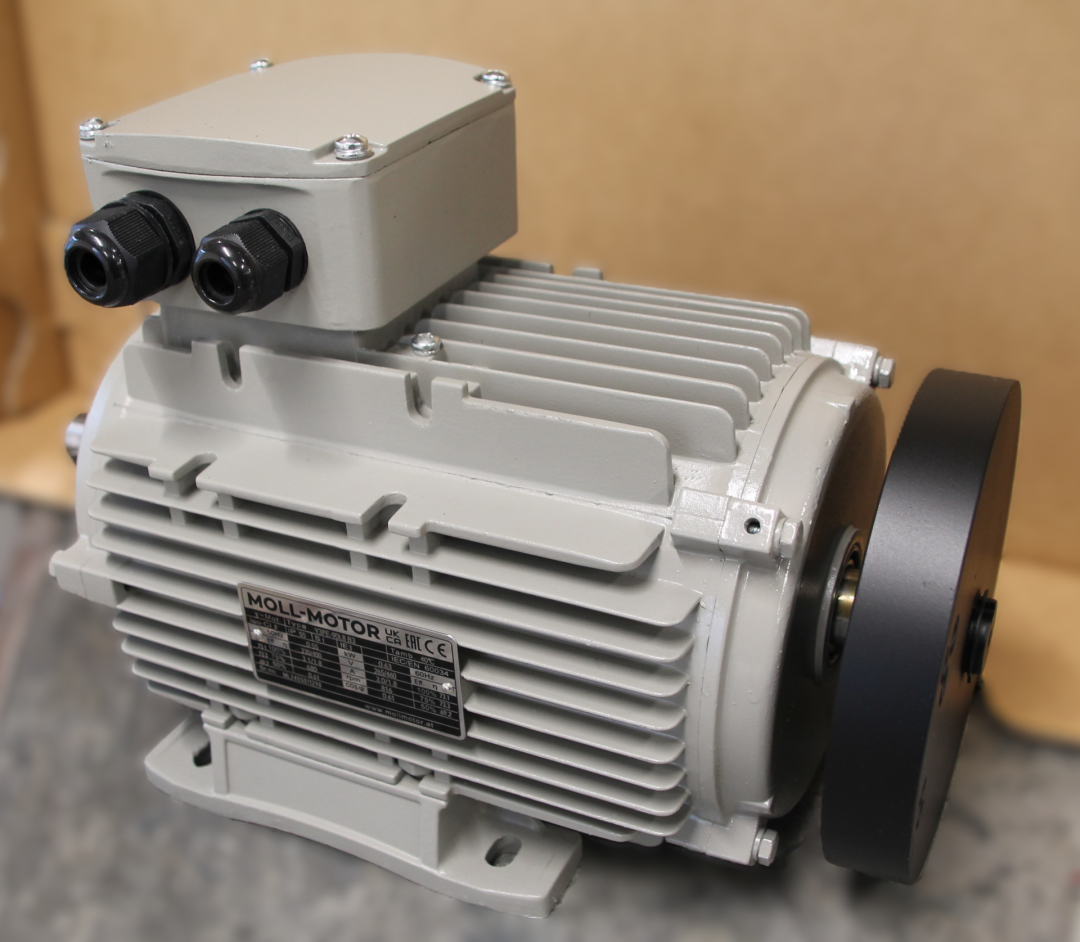

The machine control system coordinates 19 vacuum pumps to automatically maintain the vacuum at different levels. In cooperation with a major supplier of vacuum equipment, we defined the necessary parameters, put together the appropriate switchgear combination, and took over the planning and implementation. With regard to the components used, MOLL-MOTOR focuses on customer benefit; we are not bound to any particular supplier.

The switchgear cabinet shown in the photos, delivered in June, was a larger individual project, the connected load is ~230kW. It is now being used in Upper Austria, a province where MOLL-MOTOR traditionally has many customers and a strong market position.

Do you also have a control cabinet project for which you are still looking for the right partner? Our switch cabinet construction department is happy to receive your inquiry and will gladly deliver for individual projects or series. Here we can offer prototypes as well as the series production itself. Planning and production take place in Austria, at our location in Stockerau.