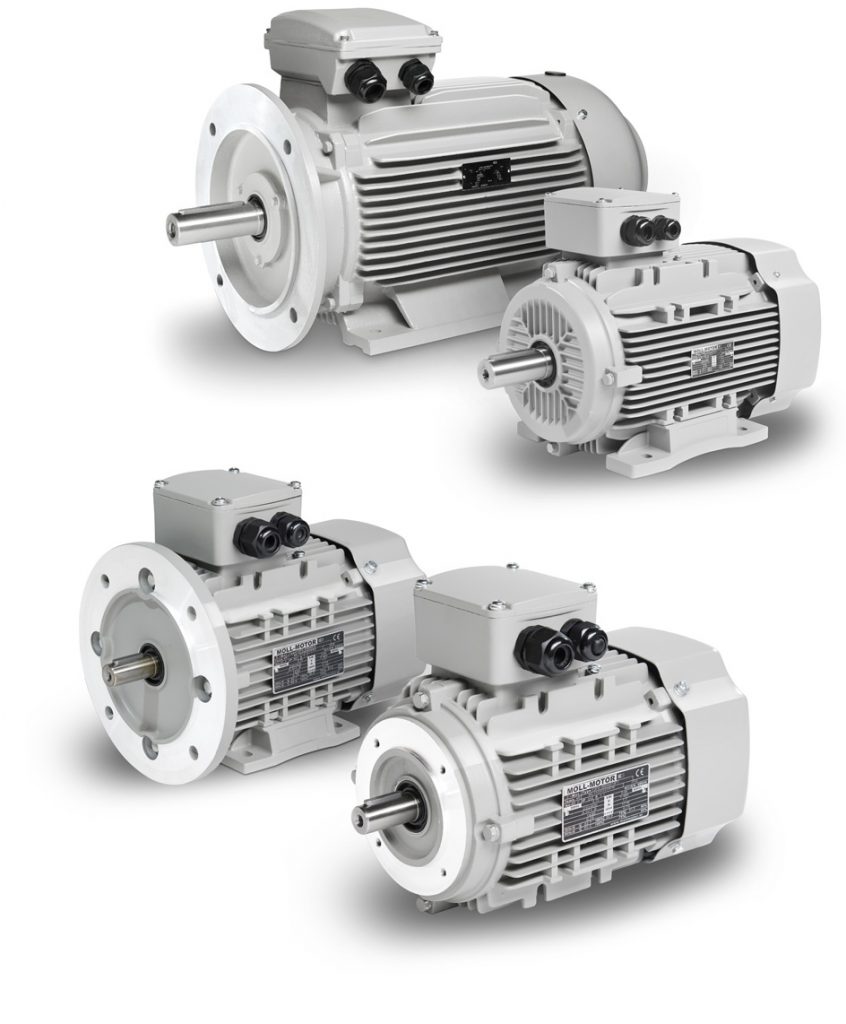

MOLL-MOTOR supplies electric motors to industry and commerce. The most important motor type is the three-phase squirrel-cage motor. This AC motor is the workhorse of the industry. In all countries of the world, stationary plants are driven by such motors, and about half of the electricity generated worldwide is used for three-phase motors.

The three-phase squirrel-cage motor is particularly robust. Since only the stationary stator needs to be connected to the mains and the rotor is rotated by induction, there is hardly any wear and tear and it can run in a wide range of environmental conditions. That is why it is so popular and used for a wide variety of applications. In industry, these include conveyor belts and screw conveyors, pumps, fans, compressors, crushers, mixers, and many more. Those who never see industrial plants from the inside can still easily spot these motors: they provide the movement for most rides in amusement parks or at public festivals.

magic word efficiency

Since such a high proportion of the world’s electricity production is used for them, high efficiency is particularly important. MOLL-MOTOR has accompanied the technical development of electric motors since 1948, which is why you can always get the latest technology from us and we will be happy to help you replace motors and save electricity. More efficient motors often pay for themselves after just a few years.

In order to meet every customer requirement, we rely on various product lines for three-phase motors.

Our premium option, manufactured in the Czech Republic, is the result of the close partnership between MOLL-MOTOR and SIEMENS, which has existed for almost 15 years. Customers often choose the Siemens product for the highest manufacturing quality, detailed documentation and customised test values. In 2023, electric motors were spun off from SIEMENS into a separate company called INNOMOTICS, which is currently still wholly owned by SIEMENS. The INNOMOTICS motor offers options that are so special that they can only be realised in cooperation with a large electronics group. Our sales engineers have access to the SIEMENS system and can immediately calculate the various special versions for you. Even after the spin-off, INNOMOTICS will continue to rely on sales via MOLL-MOTOR, as we can better serve smaller and medium-sized customers and keep motors available from stock.

The AEG brand is rightly advertised with the slogan “Good from experience”. MOLL-MOTOR has worked with AEG for decades. For customers who prefer an industrial standard motor from European production, this traditional product was a fixed starter in our delivery programme. These motors have been produced in Italy by the manufacturer LAFERT for many years and are particularly popular as replacement motors. In 2023, LAFERT decided to end its collaboration with AEG and to produce electric motors under its own brand name on packaging and nameplates in the coming years. Nevertheless, the familiar quality and reliability of the product will remain. We have a corresponding stock of motors from this series in our warehouse, the nameplates bear one of the two brand names and the spare parts in stock are suitable for motors from both brands.

We offer the greatest flexibility in terms of price and delivery time with our own brand, the Y-motors of the MOLL-MOTOR brand. They are manufactured on our behalf in factories of globally active manufacturers and delivered to us in container ships. The majority has been produced for 15 years in the same factory, which we visit annually with a delegation in times of freedom to travel. Through this close contact we ensure the necessary quality. Our mechatronics engineers have long experience with the product, so we can modify Y-motors in a variety of ways in our workshop to meet the customers’ needs. These motors are particularly popular with mechanical engineering companies, for whom we sometimes keep a year’s supply in our warehouse, or prefabricate entire assemblies and deliver them just-in-time.

Standard three-phase motors of these different product lines are ready for delivery on a daily basis. With our large stock, we cover a power range between 0.06kW and 355kW, and speeds from 750rpm to 3000rpm. By using frequency converters in the motor control, the motors can be infinitely speed-controlled. This is associated with a large energy-saving potential, e.g. for turbomachinery..

the world of electric motors

Closely related to the standard three-phase squirrel-cage motor are the following other types of motors, which are also available from us from stock or on order:

single-phase ac motors

These motors can easily be confused with three-phase motors. They have the same housing, the same speeds and power levels and work equally according to the induction principle. They also have a winding with enamelled copper wires, but the structure is different. Instead of a symmetrical arrangement for the three phases of the three-phase current, they have a main winding and an auxiliary winding. The main winding is supplied directly with alternating current, as it can be taken from any household socket. The auxiliary winding is supplied by one or two capacitors, which provide a phase shift. Single-phase motors with only one capacitor often have a starting torque <1, e.g. below the torque at rated speed. Therefore, for some applications (e.g. piston machines), motors with a second capacitor must be used, which is only active at start-up. As with three-phase motors, we rely on our own brand from the Far East and products from Europe for single-phase motors, and can supply both versions from stock.

Explosion-proof motors

If electrical equipment is operated in an environment where gas can escape or flammable dust is in the air, devastating explosions can occur. Explosion protection is mandatory for such environments. MOLL-MOTOR works with European manufacturers who produce three-phase motors specifically for such applications, supplying them to refineries, paint mixing plants, mills and warehouses. Especially for flameproof motors for use in explosion hazard zone 1, MOLL-MOTOR has a highly competitive range of motors available from stock.

Pole-changing three-phase motors

If the speed of a machine is to be changed in two stages, pole-changing three-phase motors are used. They have either a special Dahlander winding or two separate windings in the stator. This allows the machine to be started at one speed and then switched to another speed. Two different basic designs are common: In one design, the power at both speeds is designed in such a way that the same torque acts at both speeds. In the second design, the “fan motors”, the powers are designed in such a way that a quadratically higher torque is effective at the higher speed. Such motors are mainly used in fluid flow machines such as pumps and fans, because when air and water accelerate, the counter-torque increases with the square of the speed.

Flat and Circular saw motors

For circular saws and stone processing machines very flat built motors with low shaft height are used, which can be supplied for single-phase or three-phase operation, with electromagnetic brake, counter current brake or without brake. We can supply the most common powers and speeds at any time.

Brake motors

When a three-phase squirrel-cage motor is switched off, the shaft continues to rotate for some time. In some applications, this continued rotation must be prevented, which is why brake motors are used. The structure of the motor is essentially the same as that of the three-phase motor, but it is supplemented by an electromagnetic brake. The brake is usually connected in such a way that if the power supply is interrupted, it will be activated immediately and the motor will stop. Brakes have different braking torque. Weak brakes can only stop the motor, others can hold larger loads, e.g. prevent a loaded, upward leading conveyor belt from starting to run backwards under the load. The power supply to the brakes can also be provided in various ways. Either it is done via a rectifier with direct current, or directly with alternating current, which enables a faster release time. Separate control of the brake is also possible.

Our preferred partner for brake motors is the Italian manufacturer MGM, which integrates powerful and fast AC brakes. This also enables us to implement projects with particularly fail-safe dual brake motors, which are particularly in demand from customers in the theatre technology sector. In the field of DC brakes, we established brake assembly on Y motors in-house in 2023, which enabled us to increase the variety of speeds available at short notice. This enabled us to expand our position as a preferred partner for regional motor winders and service companies.

Unbalanced motors

These motors do not transmit rotary motion to a machine, but have weights mounted on both ends of the motor shaft to provide a vibrating motion. They are often used for vibratory conveying systems for bulk material, in container construction and at concrete or gravel works for screening systems. Here too, the most common types are in our stock.

other available products in the category motors

Medium and high voltage motors, Slip ring motors, Drum motors, High frequency motors, High heat resistant motors, Water cooled motors, Customised built-in and special motors, Submersible motors, Spindle motors Rotary field magnets, Shaded pole motors, Reluctance motors, Torque motors, Synchronous motors, Frequency converter motors DC motors, Permanent magnet DC motors, Servo motors, Small motors, Rotating frequency converters, Coolant pumps, Motor switches & motor protection switch